As many of you may already be aware, not all Spray Paints are equal.

However, when working with 2K paint in particular you need to be aware of the extensive health risks associated with working with an isocyanate-based paint.

Most motor and building trades use 2K paint which, if using an isocyanate-based paint, increases the probability of developing asthma by a multiple of 90. Also, the Health and Safety Executive (HSE) reports that every year around 50 sprayers are diagnosed with isocyanate asthma and most have to leave the industry. Even at very low exposure levels, attacks can still be triggered. Other illnesses are reported to have been caused directly from isocyanate-based paints such as Dermatitis, and even Cancer in some extreme cases.

Most motor and building trades use 2K paint which, if using an isocyanate-based paint, increases the probability of developing asthma by a multiple of 90. Also, the Health and Safety Executive (HSE) reports that every year around 50 sprayers are diagnosed with isocyanate asthma and most have to leave the industry. Even at very low exposure levels, attacks can still be triggered. Other illnesses are reported to have been caused directly from isocyanate-based paints such as Dermatitis, and even Cancer in some extreme cases.

Now of course, you as a user may be thinking “Well, I’m ok, I have been regularly tested for isocyanate levels and I used the right equipment”, or “I can work in a booth so the air is kept clean” or “The biggest issue is through the skin and I protect myself”, etc. But we would point out that just because nothing has happened yet, it doesn’t necessarily mean that nothing will happen in future. It’s certainly something to keep in mind.

It is essential to wear the right equipment – only an air-fed breathing apparatus is suitable for high pressure spraying with isocyanate paints, the common filter masks are not acceptable. Many sprayers remove their masks after spraying, believing it to be safe, but the air still contains large amounts of mist which is invisible to the eyes but not the lungs.

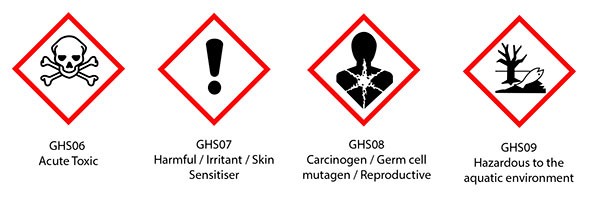

Isocyanates are hazardous chemicals.

If you’re doing touch up work with an Aerosol and using the 2K pack can with isocyanate-based paint, then you should at least wear the air filters mask and eye protection along with gloves and overalls.

More often than not with modern spray booths there is good filtration system, so a lot of people believe that all the air is filtered. Whilst a lot of the air is filtered, most spray booths take around 5mins or more to clear, so it is essential you keep your apparatus on for a while after spraying. Spray rooms are generally much slower to clear all air – at least an hour or more. It is important to note that the levels of isocyanate in spray have measured up to 300 times the workplace exposure limit.

1 in 10 people who get asthma from isocyanates in body shops are not sprayers.

When it comes to spraying outside on buildings, whether carrying out touch up work such as making sure screws or connectors match the colour of the substrate panels, it is still crucial to understand the associated risks of isocyanates. Many people carrying out this kind of touch up work will use Aerosols to do the job, and even though it would appear less of a risk spraying outside, in fact, large quantities of paint mist are spread in seconds of activation, endangering the health of anyone – both human and animal – in the local vicinity. It is vital to understand that spraying outdoors doesn’t necessarily mean you’re safer. It just means that the user won’t be able to spot the risks so easily.

Yes, we’re glad you asked!

Isocyanate is a type of hardener used to cure the 2K or 2-pack paint. Most do not question the old system; people do not know the harm isocyanates cause to them and those around. However, the alternative is quite simple – a non-isocyanates hardener used to cure 2K paint is just as effective, with all the benefits and none of the health risks associated with isocyanates.

We are one of the first custom filled spray paint providers to offer the non-isocyanate-based hardener in our 2K paints. We call it 2K ADC which stands for Air Dry Converted, which is the alternative to the old system.

We challenge anyone to find any difference in the result, we bet you won’t! The only difference is that your body will thank you for the change.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behaviour, unique IDs, user accounts on this site etc. Not consenting or withdrawing consent, may adversely affect certain features and functions.